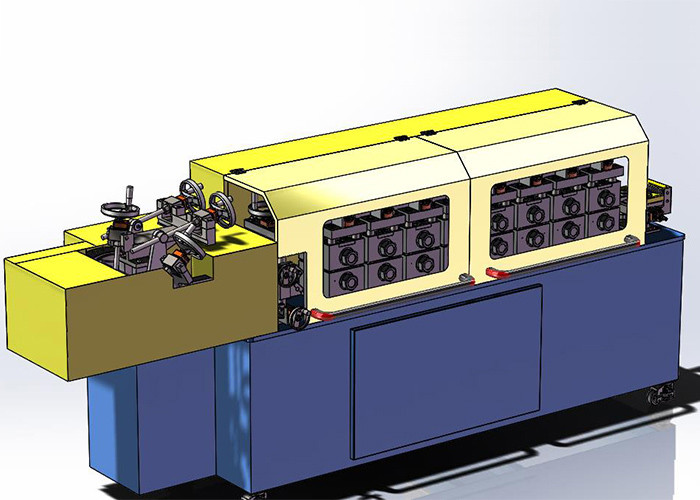

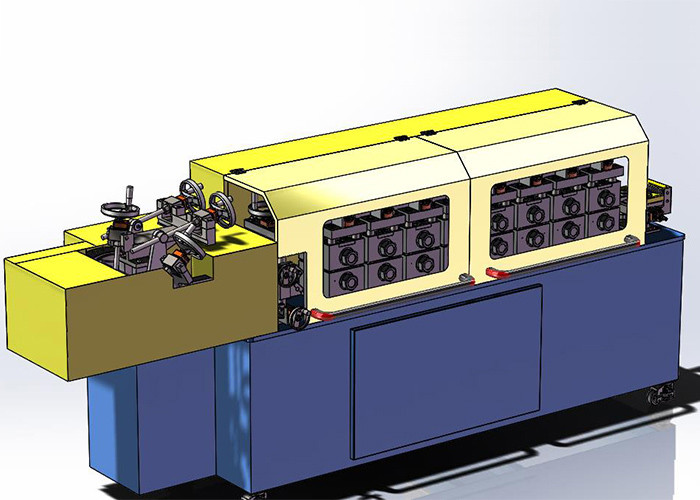

Stainless Steel Aircraft Clamps Cold Roll Forming Machine

Roll Forming Working Process

Decolier ---- Straightening ---- Roll Forming ---- Bending ---- Cut

Off

2in1 Decoiler and Straightening Machine with Pressing Arm

| Type | HBL-300L |

| Width of Strip | 30-100mm |

| Thickness of Strip | ≤3.5mm |

| Inner Diameter of Coil | ф480-520 mm |

| Outer Diameter of Coil | φ1300mm |

| Expand Way | Manual |

| Loading Weight | ≤1T |

| Roller Arrangement | 7 Rollers |

| Arrange mode | 4-Point Independent |

| Speed | Max16m/min |

| Total Power | 4KW |

Guide Device

Accurate introduction of the first forming wheel, with digital

display, detection of head and tail of coils.

Roll Forming

Type | GD100 |

Stations | 8 |

Driven Method | Gears |

Forming Passes | Material 45# High precision guide pillar bracket. Visual display is used to

adjust the upper and lower rollers. |

Passes Pitch | 200mm |

Width of Coil | Max. 100mm |

Thickness of Coil | Max. 2mm |

Diameter of Shafts | Φ50mm Material: 42CrMo Hardening treatment |

Material of Roller | Cr12Mov Hardness: HRC60-62° |

Main Driven Motor | 11KW Frequency conversion brake motor |

Bending and Cut off Device | 1 set |

Lubrication System

The lubrication system for segment forming will be self-contained

within the machine.

The excess lubrication from the forming process will be

re-circulated, filtered and re-used.

Guardings and Control System

All PLC programmes and any on-screen instructions must be in the

English language.The operator controls will be mounted in a

location, which best suits, the safe operation of the machine.

At least one Emergency stop will be fitted at the operator position

and others, as the design requires.

The equipment will be run through a PLC with instructions/messages

displayed on a small HMI screen. The control system should include,

at minimum, the following

Machine operation monitoring.

List of Inputs and Outputs and their condition

Simple operator interface using push buttons or touch screen.

Where machine positions/settings are required for different

products, these settings must be controlled via the HMI. The HMI

will be used to call the correct program for the particular product

with all machine settings automatically transferred. The program

should also show digital readout’s of diameter, & pinch rollers

position, etc.

FAQ

Q: What products can this machine produce?

A: Auto V-band Clamps, ring clamps, G coulpings, Flanges, Gaskets,

Aircraft Clamps

Q: What is the production speed?

A: Our company adopts servo motor, the speed can be controlled,

according to the material thickness and diameter of the product,

all of which can meet the requirements of customers.

Q: What are the advantages?

A: This roll forming machine we developed the latest technology to

produce clamps, through one-time roll forming to complete, instead

of the previous use of punch and other processes.