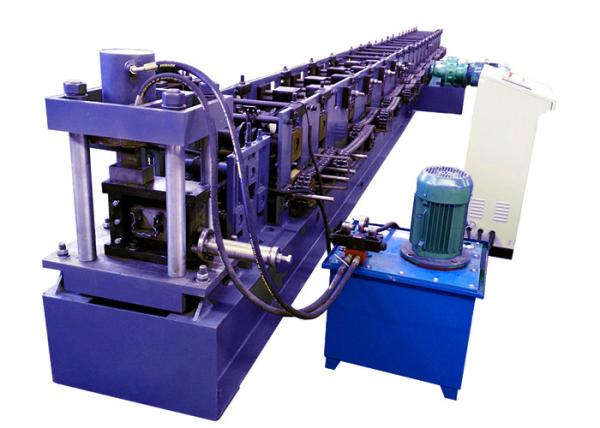

Light Duty Supermarket Storage Rack Roll Forming Machine

Description of Stroage Rack Roll Forming Machine

1. Manual coiler

power: manual uncoiler, maximum capacity 5T

Applicable to coil inner diameter: 508mm, applicable to coil

maximum outer diameter: 1000mm

The manual power supply expands the inner surface of the coil.

2. Flying saw cutting

1) Continuous cutting;

2) The blade material is Cr12, which has been quenched.

3) Welded frame, good rigidity.

4) The cutting frame is heat treated to avoid deformation of the

final product. Cut length tolerance ± 2 mm.

5) The cutting power is provided by the hydraulic station.

6) The final product can be cut according to the set length in PLC

controller, and the length is automatically measured by encoder.

When the final product reaches the set length, the machine will

stop automatically cutting the product. When this is done, the

machine will continue to run.

3. PLC control system

1) The system adopts delta programmable controller (PLC) to control

all work actions. The production quantity and the length of each

piece will be measured automatically. Easy to control roll forming

machine.

2) Delta frequency converter speed control technology to achieve

automatic production.

3) Enter the text screen and cancel the working data.

4) Friendly human-machine interface system, which can set the

batch, length and quantity of workpieces.

5) Encoder counting, with the function of counting and measuring

length.

6) Suitable power supply voltage: 380V / 50 Hz / 3 phase (can be

designed according to the buyer's requirements)

Components for punching storage rack upright roll forming machine

| Name | Quantity | Units |

| Decoiler | 1 | Set |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set |

| Cut Equipment | 1 | Set |

| Hydraulic system | 1 | Set |

| Electric control system | 1 | Set |

| Supporter/Automatic Stacker | 1 | Set |

Main Technical Parameters of Shelf Roll Forming Machine

| NO. | Item | Unit | Parameter | Remark |

1 | Material | Type | |

galvanized sheet,mild steel,etc, | |

| Strength of material sheet | Map | ≥350 | |

| Thickness of material sheet | mm | 1.2~2.5 | customizable |

| 2 | Profile sizes | mm | See Figure | |

| 3 | Production speed | m/min | 6~8 | customizable |

| 4 | Material of roller | | GCr15 quenching treatment | |

| 5 | Drive type | | Gearbox driven | |

| 6 | Motor Power | kw |

About 45 | |

| 7 | Electric control system | | PLC variable frequency control | |

| 8 | Dimensions(Length*width*height) | m | 35X4X3.9 | |

| 1. Profile | .Thickness:2.0mm |

| 2. Process flow | Decoiling---feeding---leveling---punching---forming---cutting---production |

| 3. Manual decoiler | 1).Material coil inner diameter: 450mm-550mm

2).Max coil width: 600mm

3).Carrying capacity: 1500kg |

| 4. Punching machine | 60t Automatic punch holes(with one set of mold) |

| 5. Forming system | 1).Number of forming steps:2 steps feeding rollers,4 steps leveling

rollers, 12steps forming rollers,

1).Shaft material:45# steel

Roller material:45# steel

Outer diameter:80mm

2).Transport: by chain Chain:1 inch

3).Forming speed:5-10m/min

4).Motor:11 kw

5).Voltage:380v,50Hz,3 phase

6)Size of the machine line :9.5*1.5*1.2m

7)Weight :6tons |

| 6.Cutting system | 1).Material: blade and mold material: Cr12 steel with quenched

treated 60-62℃

2).Cutting system:advanced hydraulic drive, automatic cutting after

forming, no distorting or wasting, high level safety factor. |

| 7.Control system | 1). Screen: Delta screen from Taiwan

2). PLC: Delta DVP14ES from Taiwan

3). Coder: ENC-1-1-1T-24 from South Korea |

| 8. Hydraulic | 1). Advanced hydraulic system from Taiwan

2). Power:5.5kw |

| 9. Spare Parts | 1).Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2).Rubber mat 1 pcs;

3).Bolt spanner 1 pcs |

Shelf Roll Forming Machine Woring Process

Decoiler ----- Leveling (Straightening) ----- Roll Forming -----

Punching ----- Cutting ----- Unloading

Or

Decoiler ----- Leveling (Straightening) ----- Punching ----- Roll

Forming ----- Cutting ----- Unloading